Product Details

Certification: ISO9001:2008

Payment & Shipping Terms:

Minimum Order Quantity: 1 set

Price: negotiation

Packaging Details: wooden case

Delivery Time: 15 working days

Supply Ability: 2000 sets

Detailed Product Description

| Product Name: | Fiber Laser Cutting Machine | Laser Type: | Fiber Laser |

|---|---|---|---|

| Laser Power: | 500w,800w,1000w | Working Area: | 3000*1500mm |

| Cutting Head: | Raytools | Power Supply: | 380V/50Hz |

| Warranty: | 1 Year |

Machine Features

CNC Metal Fiber Laser Cutting Machine mechanical servo cutting head direct contacts with the sheet material, so that the laser focal length remains the same, and cutting speed and quality are the same in the whole working area. The machine uses dual-rail positioning, ball screws transmission, which bring fast speed, high accuracy, stable movement, good dynamic performance and long lifetime. In machine table lengthwise and crosswise movement directions, there are over-travel limit switches and polyurethane anti-collision strips in case of limit switch failure, which greatly ensure the machine operating safety. Automatic programming system directly generates graphic files to machining program, computer simulates processing path, and software automatically nests materials, which improve processing efficiency and material utilization.

Fiber Laser Cutting Machine Advantages

1. High-quality laser optics system and excellent attachments. Best quality with best price.

2. Efficient and stable programing and control system, easy to learn. Compatible with many kinds of CAD files and formats. Intelligent-layout and cost-saving.

3. Energy-saving and cost-saving. Laser machine is stable and easy to maintain.

4. No need mold and flexible manufacturing, which can meet any requirement of all kinds of special workpieces.

5. Highly-efficient cutting and good cutting effect. No noise and no vibration. Cutting speed can be up to tens of meters per minute when cutting thin metal sheet. Quality for cutting edge is excellent.

6. Imported servo motor, this can make sure to much more improve stability and reliability of laser machines, at the same time can ensure precision of processing.

Technical parameters

| Model | laser fiber laser cutting machine |

| Working size: (L*W) | 2500mm*1300mm, 1500m*3000mm,2000mm*3000mm |

| Laser tube | 500W,800w,1000w |

| X,Y,Z axis range: | 2525mm/1325mm/100mm |

| The thickness of the material | 0.1-3mm(Depending on the material) |

| Maximum cutting thickness | 3mm |

| Position accuracy | 0.02mm |

| Maximum moving speed | 25m/min |

| Operating temperature | 0℃-40℃ |

| Control system | DSP |

| Drive type of X, Y axis | imported servo drive( Panasonic, Japan) |

| Machine size(L*W*H) | 3800*1850*1300mm |

| Cooling System | Water Cooling |

| Technical Class | Continuous Wave Laser |

| Structure Type | Gantry Type |

| Laser Technology | Laser Vapor Cutting |

| Package | wooden case |

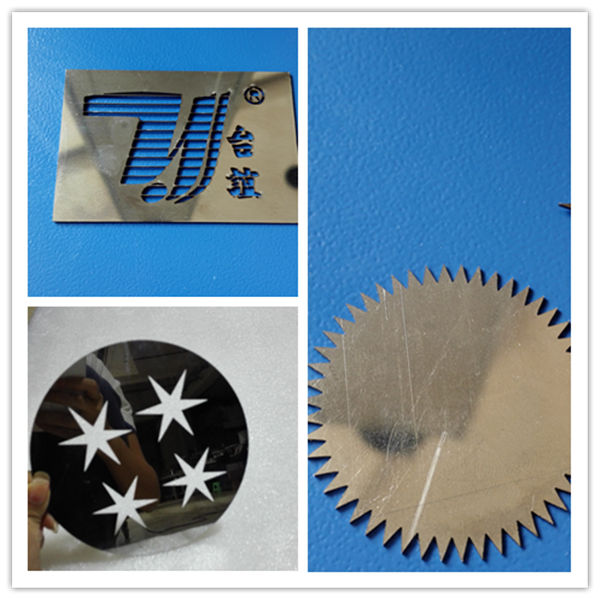

Application industry

Widely used in electric power, automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising logo, car decoration, sheet metal production, lighting hardware, display equipment, precision parts,

Applicable materials

Can be cut a variety of metal sheet, pipe (pipe cutting tube can be another pipe), mainly for stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass plate, aluminum, manganese steel, Metal and other materials of professional fast cutting;