Product Details

Detailed Product Description

| Product Name: | Metal Sheet Laser Cutter | Laser Power: | 1000w 1500w |

|---|---|---|---|

| Laser Wavelength: | 1080nm | Working Area: | 3000*1500mm |

| Cutting Thickness: | 0-16MM (depends On Laser Power) | Power Supply: | 380v |

| Warranty: | 1 Year |

Product Desciption

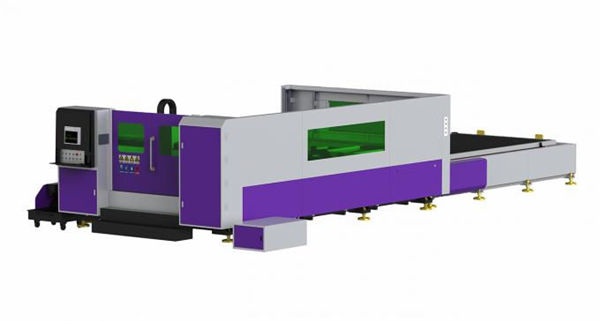

1. Integrated machine design:left and right collecting drawer on the left and right side of the machine,highly saving space.

2. Stability and reliability of light path system and control system.

3. Fiber laser has high and stable function and lifespan which is over 100000 hours.

4. Higher cutting quality and efficiency with cutting speed being up to 25m/min with perfect cutting edge.

5. High performance reducer, gear and rack; Japanese guide and ball screw.

Main Features of Sheet Metal Laser Cutting Machine

1. The middle part of the two platforms are not in the same level, which can Save time for feeding and unloading material in short time.

2. Fully enclosed design can greatly reduce damage to the health from the laser, especially for those countries who strictly required to the environmental protection.

3. The exchange platform with heavy capacity can be placed 8-10 mm carbon steel plate. The table has universal balls. There is a sheet metal clamping device beside the table, which can firmly fix the materials on the table to avoide workpiece movement.

4. If it was powered off or the chain was pulled off , the platform can be pushed in by hand. At the same time it has anti-collision protection device on the left side of the machine to protect of the machine from damaging.

5. Working platform plate was made of a thickness of 3 mm carbon steel plate, the service life is long. it dosen’t need the replacement in 8 months to 1 year.

6. The overall steel beam is very steel, the machine beam used a 17 mm thickness plate, and beam base’s thickness is about 30 mm.

7. Dust cover is made of the fire-retardant materials.There will not be break and pull off with a long time use, at the same time it can prevent the spark burning.

8. Using the well-known brand of Taiwan helical rack, Taiwan's silver (HIWIN) 30 rail, good quality electronic devices, and Franch drive motor to ensure the accuracy of the machine work.

9. Faster Acceleration , repeated positioning accuracy is about 0.03mm,and its cutting accuracy can reach 7-8 silk.

Technical Specifications

| Model | RL-1530F |

| Laser wavelength | 1080nm |

| Cutting thickness | 0.2-16mm |

| Laser output power | 1000W |

| Maximum processing range | 3000 *1500mm |

| Machine drive mode | imported rack gear and pinon drive |

| Y X. axis positioning accuracy | ±0.01mm |

| X.Y axis repeat positioning accuracy | ±0.01mm |

| Power supply mode | 380V / 50Hz |

| Maximum cutting speed | 45m/min |

| Minimum cutting line width | 0.02mm |

| Cooling mode | 3P Water cooling |

Laser Cutting Machine Details

Applied materials

Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

Applied Industries

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.