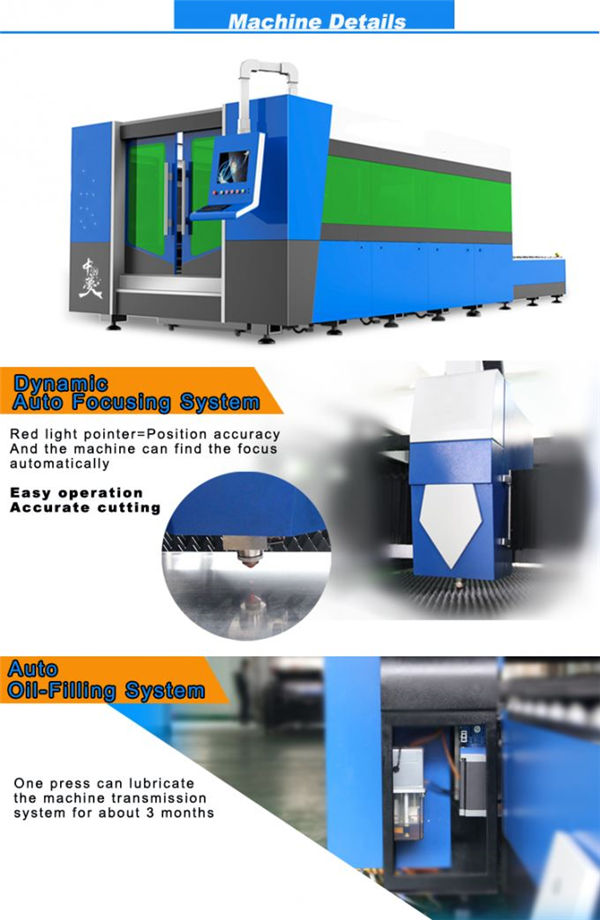

Product Details

Certification: CE

Payment & Shipping Terms:

Minimum Order Quantity: 1Set

Price: 250000USD/SET

Packaging Details: 1*40GP container

Delivery Time: 30days

Payment Terms: L/C, D/A, T/T, D/P, Western Union

Detailed Product Description

| Product Name:: | 6kw Fiber Laser Cutting Machine Made In China Taiwan Taiyi | CNC Or Not:: | Yes |

|---|---|---|---|

| Cooling Mode:: | Water Cooling | Graphic Format Supported:: | AI, BMP, DST, DWG, DXF, DXP, LAS, PLT |

| After-sales Service Provided:: | Engineers Available To Service Machinery Overseas | Repeating Accuracy:: | +-0.03mm |

| Operating Temperature:: | 0°C-45°C | Cutting Area: | 3000x1500mm |

Machine Application

Applicable Material:

Fiber Laser Cutting machine is used for cutting sheet metal&pipes:

Stainless Steel, Mild Steel, Carbon Steel, Alloy Steel, Spring Steel, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum, Copper, Brass, Bronze, Gold, Silver, Titanium, etc..

Applicable Industries:

Fiber Laser Cutting machine is mainly applied in metal processing: metal plate&tubes, secure door, charging pile, auto parts, spaceflight, electronic parts, subway parts, machinery, precision components, ships, elevator, kitchenware, gifts and crafts, , metal art ware, tool processing, adornment, advertising letters, ironware, chassis, racks and cabinets, hardware, glasses frame, nameplates, etc..

Specification

| Laser Source | IPG/Nlight/Raycus/Max |

| Machine Body | gantry structure |

| Max running speed | 120m/min |

| X/Y positioning accuracy | ±0.03mm |

| Power Supply | 380V 50Hz/60Hz |

| X/Y repeated location precision | ±0.03mm |

| Running Temperature | 0°C-40°C |

| Max Acceleration | 2G |

| Machine gross power | 46KW |

| Applied Materials | Thin mild steel, stainless steel and other kinds of metallic sheets |

| Cutting Area | 3000mm*1500mm/4000mm*2000mm/6000mm*2000mm |

| Total Weight | 8600KGS |

Sample display

Why Choose Us

1. Brand Protection

2. Quality Assurance & High cost-effective

3. China manufacturer with competitive price

4. Multi-language service with quick response

5. Engineer overseas service available

6. OEM available

Training

After signing the contract, your company can arrange technologist to our factory or we can arrange engineer to customer's factory. The training content as follow:

a) Common cutting software training;

b) Machine on and off procedures;

c) The significance of control panel and software parameters, parameters range setting;

d) Basic cleaning and maintenance of the machine;

e) Common Hardware Trouble shooting;

Warranty

a). 2 Year for the whole machine(Man-made Damage is negotiated.).

b). Laser source 2 Year warranty

c). Lifelong maintenance and spare parts supply

d). Free training for operation staffs. (engineer can go abroad is negotiated.)

FAQ for Laser Cutting Machine

Q1: I know nothing about this machine, what type of machine should I choose?

We will help you choose the suitable machine and share you the solution; you can share us what material will you cut, the material thickness and working size.

Q2: When I got this machine, but I don’t know how to use it. What should I do?

We will send English manual and Operation Video and for the machine. Our engineer will do training online. If needed, we can send our engineer to your site for training or you can send the operator to our factory for training.

Q3: May we know the speed of your Fiber Laser Cutting Machine as per on our demand basis?

We use Japan Servo motor and driver with big strength, so the max moving speed can reach 120m/min, max cutting speed can reach 40m/min. And the speed can reach 1.5-2m/min if you cut 4.5-5mm stainless steel.

Q4: If some problems happen to this machine, what should I do?

We provide two years machine warranty. During the two-year warranty, in case any problem for the machine, we will provide the parts free of charge (except for artificial damage). After the warranty, we still provide whole lifetime service. So any doubts, just let us know, we will give you solutions.

Q5: About accuracy, we have observed that after some time "Machine accuracy can increase gradually" and after long time, the difference reach to its maximum level. How about your machine?

The frame of the machine is annealed, it can support shock resistance(the machine will deform if without annealing ). So the accuracy of the machine can keep its original accuracy for 4-5years. The weight of the machine can reach 4.5t-5.0t. It also can let the machine have higher accuracy and higher stability.

Q6: What’s package, will it protect the products?

A: Nude Packing for big parts after plastic film covering. The small parts packed into wooden cases which is suitable for seaworthy transportation.

Q7: How is the shipping method?

A: As per your actual address, we can effect shipment by sea, by air, by truck or railway. Also we can send the machine to your worksite as per your requirement .