Product Details

Certification: CE

Payment & Shipping Terms:

Minimum Order Quantity: 1Set

Price: Negotiable

Packaging Details: 1*40GP container

Delivery Time: 30days

Payment Terms: L/C, D/A, T/T, D/P, Western Union

Detailed Product Description

| Application:: | All Metal Material | Laser Type:: | Fiber |

|---|---|---|---|

| Product: | Laser Cutting Machine | Min.line Width: | 0.1mm |

| Control Software:: | Cypcut | Graphic Format Supported:: | AI, BMP, DST, DWG, DXF, DXP, LAS, PLT |

| Brand Name:: | TAIYI LASER | Repeating Accuracy:: | +-0.03mm |

| Operating Temperature:: | 0°C-45°C | Cooling Mode: | Water Cooling |

| Laser Source: | Chinese Or Imported | Voltage:: | AC380V±10% 50HZ(60HZ) |

| Cutting Area: | ø40-ø200 X 6000mm |

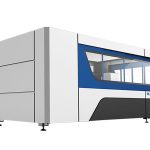

Introduction of laser cutting machine

The laser cutting machine adopts the current most advanced laser technology manufacturers from Germany,the UK imports dedicated laser cavity ,it has the merits of effect cooing and high electronic-optical conversion efficiency.In structure,the machine have a structure,it has functions of optical previewing and focus instructing with a more aesthetic appearance and more convenient operation.The machine is equipped with the latest external water cooling system with very low running noise and high accuracy temperature regulator,which provide a reliable guarantee for a long time running.

Main Features

1) The Accurl laser cutting machine with the highest precision in China, it can cut small metal bike design with size of half a coin and perfectly cut 6mm mild steel,120 holes can be cut within one minute.

2) 600℃ heat treatment, 24 hours cooling in the oven, 8 meters gantry milling, accurate CO2 protection welding, to make sure 20 years usage without deformation.

3) Using laser electrical cabinet integration design, cover small area , save space, minimalist design.

4) Scrap car symmetrical design, both sides can clean up the waste; Put machine to the romm has no left and right requirements; Pneumatic lifter device to prevent the material from scratching.

5) Specially used for cutting 0.5-6mm carbon steel, 0.5-5mm stainless steel, galvanized steel, electrolytic zinc-coated steel sheet, silicon steel and other kinds of thin metal sheets.1000W can cut 3mm aluminum and 2mm copper.

Specification

| Laser source medium | Fiber |

| Cutting range (L * W) | ø40-ø200 x 6000mm |

| Z axle stroke | 250 mm |

| Max. positioning speed | 120 m/min |

| X,Y axle Max. accelerate speed | 1.0G |

| Cooling form | Water cooling |

| Laser wavelength | 1070nm |

| Output power of laser source

| 500W/1000W / 1500W / 2000W 2500W / 3000W / 4000W (Optional) |

| Min. cutting gap | ≤ 0.1 mm |

| Positioning accuracy of X, Y and Z axles | ± 0.03 mm |

| Repeated positioning accuracy of X, Y and Z axles | ± 0.01 mm |

| Thickness of cutting material (according to material) | 0.2 - 25 mm |

| Driver model | Imported servo motor |

| Power requirement | 380V, 50/60 Hz |

| Working temperature | 0-45℃ |

| Continuous working time | 24 Hours |

| Machine weight | About 4000 Kgs |

| Total protection level of power supply | IP54 |

Cutting Thickness Reference Table

| Laser Power | Max cutting thickness | |||

| Carbon steel(mm) | Stainless steel(mm) | Aluminum (mm) | Brass (mm) | |

| 700W | 8 | 3 | 1 | 1 |

| 1000W | 12 | 4 | 2 | 2.5 |

| 1500W | 14 | 5 | 4 | 3 |

| 2000W | 16 | 6 | 5 | 4 |

| 3000W | 22 | 10 | 6 | 8 |

| Above parameter for reference only | ||||

Application

Widely used in kitchen appliance, electric control box, high-resolute device, mechanical equipment, electrical

equipment, lighting, posters, auto parts, display equipment, hardware and metal processing.

Detailed Images

| Name: Machine body and accessoriea.600℃ heat treatment, 24 hours cooling in the oven, accurate CO2 protection welding, to make sure 20 years usage without deformation. b.Synchronous X/Y/Z axes: The Z-axis can run 150mm, suitable for cutting many varieties of metal sheets. c.High quality guarantees its durability and easier maintenance. | |

| Name:AC servo motor & driverThe imported servo motor (Y-axis driven by two servo motors) along with the sophisticated planetary reducer ensures steady, precise and reliable drive. | |

| Name:Precision Linear GuidesAdvanced cutting system, laser power and servo movement suit each other perfectly, imported high precision gear and rack drive system, exchangeable double work table, to ensure higher processing speed and accuracy.. | |

| Name:Cutting headThe contactless cutting head has the function of auto height tracking and anti-collision, which greatly improves cutting speed, smoothness and cutting accuracy under the same output power. In a word, the cutting efficiency can be increased. | |

| Name:Laser sourcefast speed,high precision cutting line, and smooth cutting edge |

Cutting Samples

Training

After-sales service, from training to machine installation (3 ways):

1. Training video and user's manual in English to be offered for installation, operation, maintenance and trouble-shooting, and technical guide to be offered by e-mail, fax, telephone/whatsapp /skype//and so on, when you meet some problems of installation, using or adjusting.

2. Your company can arrange technologist come our factory to learn basic knowledge of equipment and operating essentials , sufficient training time about 3-5days , the training content is as follows:

a) Common drawing software training ;

b) Machine on and off training procedures ;

c) The significance of control panel and software parameters, parameters range’s setting

d) Basic cleaning and maintenance of the machine ;

e) Common Hardware Troubleshooting ;

f) Caution of operation.

3.Door-to-door instruction training service. visa, traveling expenses and accommodation will be at customer's cost. It's better to arrange a translator for both of our engineers during the training period. Training Time: 3-5days.

FAQ

Q1: what kind of machine I should choose?

It is just easy to choose from. You need to tell us what you want to do, then we will give you perfect solutions and suggestions.

Q2: I don’t know how to use it. What should I do?

We will send an English manual with the machine. If you still have some doubts, we can talk by telephone or Skype and e-mail.

Q3: If some problems happen to this machine during the warranty period, what should I do?

We also supply free life long after-sales service. So any doubts, just let us know, we will give you solutions.

Q4: Before sending me an inquiry on our fiber laser, it is better for you to provide me with the following information?

1)Your metal or non-metal material size. Because in our factory, we have different models according to the working area.

2)Your materials.

3)You want to engrave or cut?

If cut, could you tell me your cutting thickness? Because different cutting thickness needs different laser tube power and laser power supplier.