Product Details

Certification: ISO9001:2008

Payment & Shipping Terms:

Minimum Order Quantity: 1 set

Price: negotiation

Packaging Details: wooden case

Delivery Time: 15 working days

Supply Ability: 2000 sets

Detailed Product Description

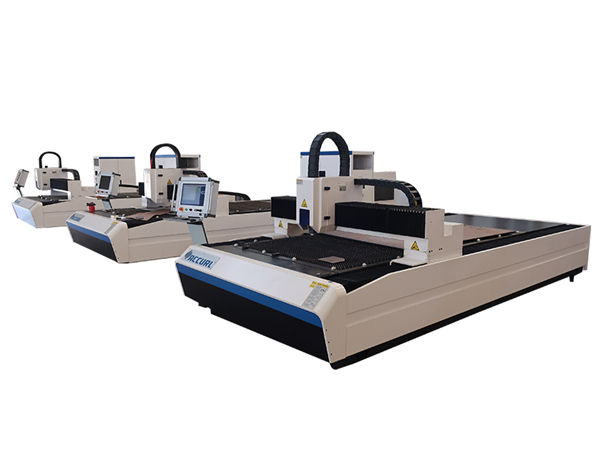

| Product Name: | Fiber Laser Cutting Machine | Laser Type: | Fiber Laser |

|---|---|---|---|

| Laser Power: | 500w,800w,1000w | Working Area: | 3000*1500mm |

| Cutting Head: | Raytools | Power Supply: | 380V/50Hz |

| Warranty: | 1 Year |

Machine Features

1. Moved crossbeam with imported high precision racks and linear guide rail, transmission stable, working with high precision.

2. Machine tool, crossbeam and worktable adopt integral welding structure, machine tool, crossbeam and worktable adopt integral welding structure, in accordance with the standard large machine, to stress annealing after precision finishing and then for vibration aging treatment, it can completely eliminate the welding stress and processing stress, keep high-strength, high precision, and also keep the 20 years of normal use don't deformation.

3. X, Y and Z axis use imported Japan servo motor, high precision, high speed, large torque and large inertia, performance is stable and durable, ensure the high speed operation of the whole machine.

4. Based on Windows operating system, use professional Bochu cypcut numerical control system for fiber laser cutting machine, integrated with laser cutting control special function module which is powerful with a good man-machine interface and easy to operate.

5. Laser-produced without gas, it could use air to cut sheet metal.

Fiber Laser Cutting Machine Advantages

1. Excellent beam quality: Smaller focus diameter and high work efficiency, high quality.

2. High precision and high speed cutting

3. Stable running: adopting the top world import fiber lasers, stable performance, and key parts can reach

100,000 hours;

4. High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine,fiber laser cutting

machine has three times photoelectric conversion efficiency

5. Low cost: Save energy and protect environment.

6. Low maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7. Easy operations: fiber line transmission, no adjustment of optical path;

8. Super flexible optical effects: compact design, compact and easy to flexible manufacturing requirements.

Technical parameters

| Model | Rise laser fiber laser cutting machine |

| Working size: (L*W) | 2500mm*1300mm, 1500m*3000mm,2000mm*3000mm |

| Laser tube | 500W,800w,1000w |

| X,Y,Z axis range: | 2525mm/1325mm/100mm |

| The thickness of the material | 0.1-3mm(Depending on the material) |

| Maximum cutting thickness | 3mm |

| Position accuracy | 0.02mm |

| Maximum moving speed | 25m/min |

| Operating temperature | 0℃-40℃ |

| Control system | DSP |

| Drive type of X, Y axis | imported servo drive( Panasonic, Japan) |

| Machine size(L*W*H) | 3800*1850*1300mm |

| Cooling System | Water Cooling |

| Technical Class | Continuous Wave Laser |

| Structure Type | Gantry Type |

| Laser Technology | Laser Vapor Cutting |

| Package | wooden case |

Fiber cutting machine application

Manufacture industry, elevator industry, auto parts making, electrical parts making, locomotive manufacturing, agriculture and forestry machinery making, special vehicles, household appliances, tools, IT industry, kitchen supplies, decorations, craft, jewelry, etc.

Fiber laser cutting machine is professional in cutting varies metal sheets. Such as stainless steel, carbon steel, mild steel, iron, galvanized steel, titanium steel, silicon steel, brass, aluminum, titanium alloy, brass, copper, silver, gold, etc.