Product Details

Certification: CE

Payment & Shipping Terms:

Minimum Order Quantity: 1Set

Price: Negotiable

Packaging Details: 1*40GP container

Delivery Time: 30days

Payment Terms: L/C, D/A, T/T, D/P, Western Union

Detailed Product Description

| Application:: | All Metal Material | Cutting Thickness: | SS Upto 12mm, MS Upto 22cm |

|---|---|---|---|

| Laser Type:: | Imported Original Fiber Laser | Max Cutting Thickness: | 20mm/CS; 10mm/SS |

| Min.line Width: | 0.1mm | Control Software:: | Cypcut |

| Graphic Format Supported:: | AI, BMP, DST, DWG, DXF, DXP, LAS, PLT | Brand Name:: | TAIYI LASER |

| Repeating Accuracy:: | +/-0.03mm | Operating Temperature:: | 0°C-45°C |

| Cooling Mode: | Water Cooling | Laser Source: | IPG/Nlight/Raycus/Max |

| Voltage:: | AC380V±10% 50HZ(60HZ) | Cutting Area: | 3000x1500mm |

Advantage of fiber laser machine

1. Compact structure, small floor area.

2. Stability and reliability of light path system and control system.

3. High performance and low operating cost, famous IPG fiber laser with up to more than 100 thousand hours life-cycle.

4. Higher cutting quality and efficiency, cutting speed is up to 15 m/min with appearance and beautiful cutting edge.

5. High precision servo motors, lead screws and guide ways with famous brands to ensure the efficiency and accuracy, greatly increasing the stability and reliability.

Feature & Property

Adopting World Famous Germany Dlaser Fiber laser source and USA Laser Mech cutting head & Dynamic Focus System , it can cut and punch different kind of metal material with high precision and high speed.

Since laser is transmitted by fiber, it is no need to maintenance or adjusts the laser optical path. It greatly reduces the machines fault rate and prolongs the working life.

Large format cutting area meets the demands of various kinds of metal processing.

Since laser is transmitted by fiber, it is no need to maintenance or adjusts the laser optical path. It greatly reduces the machines fault rate and prolongs the working life.

Since laser is transmitted by fiber, it is no need to maintenance or adjusts the laser optical path.It greatly reduces the machines fault rate and prolongs the working life.

Specification

| Laser source medium | Fiber |

| Cutting range (L * W) | 3000 mm × 15000 mm |

| Z axle stroke | 250 mm |

| Max. positioning speed | 120 m/min |

| X,Y axle Max. accelerate speed | 1.0G |

| Cooling form | Water cooling |

| Laser wavelength | 1070nm |

| Output power of laser source

| 500W/1000W / 1500W / 2000W 2500W / 3000W / 4000W (Optional) |

| Min. cutting gap | ≤ 0.1 mm |

| Positioning accuracy of X, Y and Z axles | ± 0.03 mm |

| Repeated positioning accuracy of X, Y and Z axles | ± 0.01 mm |

| Thickness of cutting material (according to material) | 0.2 - 25 mm |

| Driver model | Imported servo motor |

| Power requirement | 380V, 50/60 Hz |

| Working temperature | 0-45℃ |

| Continuous working time | 24 Hours |

| Machine weight | About 12000 Kgs |

| Total protection level of power supply | IP54 |

Cutting materials

The fiber laser can cut all kinds of non ferrous metals, such as copper,aluminum,this high reflective materials, and tungsten,can also cut stainless steel,carbon steel, manganese steel,galvanized sheet,aluminum platform gold alloy plate, and other rare metals.

Application industry

Suitable for stainless steel, carbon steel, alloy steel, copper, brass, steel, galvanized steel, nickel titanium alloy, nickel chromium alloy and titanium alloy metal materials

Fiber laser cutting machine application:

metal cutting, electrical switch manufacturing, aerospace, food machinery, textile machinery,

engineering machinery, locomotive manufacturing, agriculture and forestry machinery, elevator manufacture, special vehicles, household appliances, tools, processing, IT manufacturing, oil machinery, food machinery, diamond tools, welding, welding gear, metal materials, decoration advertising, laser surface treatment of foreign processing services, such as all kinds of machinery processing industry.

Detailed Images

| Name:Machine body and accessories a.600℃ heat treatment, 24 hours cooling in the oven, accurate CO2 protection welding, to make sure 20 years usage without deformation. |

| Name:AC servo motor & driver The imported servo motor (Y-axis driven by two servo motors) along with the sophisticated planetary reducer ensures steady, precise and reliable drive. |

|

| Name:Precision Linear Guides Advanced cutting system, laser power and servo movement suit each other perfectly, imported high precision gear and rack drive system, exchangeable double work table, to ensure higher processing speed and accuracy.. |

| Name:Cutting head

The contactless cutting head has the function of auto height tracking and anti-collision, which greatly improves cutting speed, smoothness and cutting accuracy under the same output power. In a word, the cutting efficiency can be increased. |

|

| Name:Laser source fast speed,high precision cutting line, and smooth cutting edge |

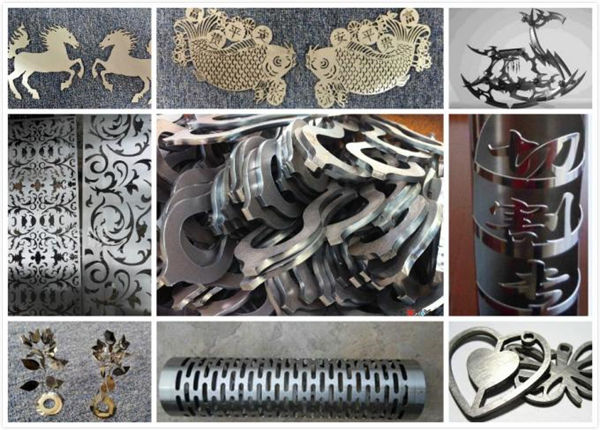

Cutting Samples

Pre-sale service

1. Free sample cutting,

For free sample cutting/testing, please send us your CAD file, we will do cutting here and make video to show you the cutting ,or send sample to you check cutting quality.

2. Customized machine design

According to customer’s application, we may revise our machine accordingly for customer’s convenience and high production efficiency.

Service after sales

A. Machine will be supplied with training video and user's manual in English for installation, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, fax, telephone, skype….

B. We offer technician to customer's site for installation and training, customer shall cover visa, ticket, local living cost.

C. Customer may come to our factory for training. We will offer training of installation, operation, machine trouble-shooting, and maintenance.

During training in our workshop, we offer free training and living cost for 7 days, limit 2 people.

Warranty

a).1Year for the whole machine(Man-made Damage is negotiated.).

b).Laser source 2 Years warranty

c).Lifelong maintenance and spare parts supply

d).Free training for operation staffs. (engineer can go abroad is negotiated.)

FAQ

Q1: How can I get the best machine for me?

You can tell us your working material, detail work by picture or vedio so that we can judge whether our machine can meet your need or not. Then we can give you the best model depends on our experience.

Q2: This is the first time I use this kind of machine, is it easy to operate?

We will send you manual and guide vedio in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can help you by "Teamviewer" online help software.Or we can talk by phone, email or other contact ways.

Q3: If the machine has problem in my place, how could I do?

We could send free parts to you in warranty period if machines have any problem under "normal use".

Q4:Do You Arrange Shipment For The Machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.