Product Details

Certification: ISO9001:2008

Payment & Shipping Terms:

Minimum Order Quantity: 1 unit

Price: negotiation

Packaging Details: Wooden Case

Delivery Time: 7-15 days

Supply Ability: 2000 units per month

Detailed Product Description

| Product Name: | Small Size 5050 High Precision Fiber Laser Cutting Machine | Laser Power: | 300w To 800w |

|---|---|---|---|

| Working Area: | 500*500mm | Max Moving Speed: | 60m/min |

| Positioning Accuracy: | ± 0.01-0.03 | Powe Supply: | 3×380V±10% 220V±10% |

| Package: | Wooden Case | Warranty: | 1 Year |

This model adopts high-precision linear motor workbench, high precision, fast speed; optional high-precision CCD automatic positioning, automatic calibration. The whole process controlled by automatic computer software, the software interface real-time feedback, timely understanding of the processing status, non-contact processing program, no mechanical stress and deformation, simple operation, high cutting precision.

1, Practical new type patent integrated design, can match with different types or manufacturers of laser source, compact structure reliable, safe, practical and reasonable.

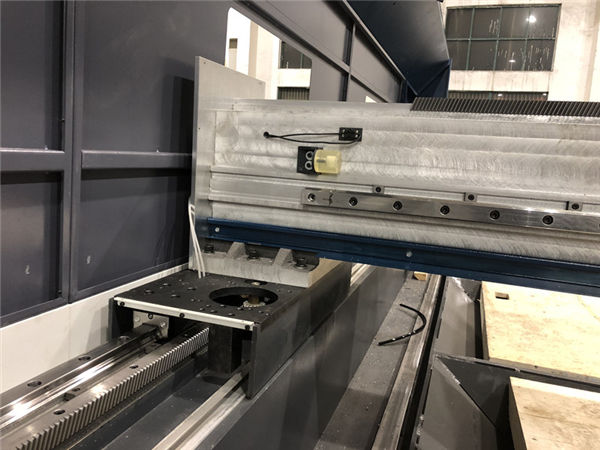

2, Using an optical marble platform, anti-vibration frame design, suitable for high speed movement, high stability.

3, High-precision, with full feedback linear motor workbench, speed is fast; large working area visual precision positioning is optional, automatic precision calibration.

4, The multi-function integrated control, independent research and development of patent software, software automatic control in processing, the software interface real-time feedback, showing all functions and all parts of processing status; non-contact processing mode, no mechanical stress and deformation.

2, Using an optical marble platform, anti-vibration frame design, suitable for high speed movement, high stability.

3, High-precision, with full feedback linear motor workbench, speed is fast; large working area visual precision positioning is optional, automatic precision calibration.

4, The multi-function integrated control, independent research and development of patent software, software automatic control in processing, the software interface real-time feedback, showing all functions and all parts of processing status; non-contact processing mode, no mechanical stress and deformation.

Configuration

| # | Item | Specification | Brand | Remark |

| 1 | Laser Source | 800W | Maxphotonics | |

| 2 | linear motor | |||

| 3 | Optical grating | resolution 0.5μm | Spain | |

| 4 | Driver | servotronix | ||

| 5 | Z axis Screw module group | |||

| 6 | Laser cutting head | BT230 | ||

| 7 | Precision linear guide rail | Hiwin | ||

| 8 | Marble | 1800*1350*200 | Shandong | |

| 9 | Organ cover | Standard | ||

| 10 | Machining material | Standard | aviation aluminum-alloy |

Parameter

| Working size | 500×500(mm) | |

| Max. Acceleration | 1.2g | |

| X AXIS | Max. Moving speed | 60m/min |

| Route | 500mm | |

| Positioning accuracy | ±0.01mm | |

| Repeatition accuracy | ±0.004mm | |

| Y AXIS | Max. Moving speed | 60m/min |

| Route | 500mm | |

| Positioning accuracy | ±0.01mm | |

| Repeatition accuracy | ±0.004mm | |

| Z AXIS | Route | 100mm |

Working condition

| 1 | Working temperature | -10℃~45℃ |

| 2 | Relativede Humidity | <90% no condenser |

| 3 | Environment | Good ventilation, no vibration |

| 4 | Power supply | 3×380V±10% 220V±10% |

| 5 | Power frequency | 50Hz |

4. Machine proposal

4. 1 The Machine rack adopts marble structure and US CNC laser cutting system. With Integrated designing, through gantry milling machine processing ,so to make the movement be accurate .linear motor driving system, friendly interface and long term stable working.

Adopted THK Japan precision linear guide rail, with high accuracy, low abrasion and easy to be assembled or exchanged.4. 2 laser cutting head

BT230 (Raytools, Switzerland brand ) laser cutting head with auto focus system. It can prevent materials waste from distortion cutting. The protection glass can keep and protect the low cost of the important optical parts inside of the cutting head. Auto focus system is suitable for non-flat metal sheet processing. Combined with high quality lasers the BT230 can be widely used in ceramic, medical, semiconductor and other industries.

4. 1 The Machine rack adopts marble structure and US CNC laser cutting system. With Integrated designing, through gantry milling machine processing ,so to make the movement be accurate .linear motor driving system, friendly interface and long term stable working.

Adopted THK Japan precision linear guide rail, with high accuracy, low abrasion and easy to be assembled or exchanged.4. 2 laser cutting head

BT230 (Raytools, Switzerland brand ) laser cutting head with auto focus system. It can prevent materials waste from distortion cutting. The protection glass can keep and protect the low cost of the important optical parts inside of the cutting head. Auto focus system is suitable for non-flat metal sheet processing. Combined with high quality lasers the BT230 can be widely used in ceramic, medical, semiconductor and other industries.

| Item | Parameter |

| collimation | 100mm |

| focus | 125mm |

| optical aperture | 25mm |

| nozzel (single) | :0.8/1.0/1.5/2.0/2.5/3.0/3.5/4.0mm |

| lens materials | quartz |

| fiber plug | QBH |

| Auxiliary pressure | Max. 20bar |

| weight | ~1.5Kg |

Control system

The use of professional PC industrial computer operation, graphical interface, easy to operate, professional cutting control software can freely design a variety of graphics and text, real-time processing, support CAD, CorelDraw and other professional mapping software.

. High-quality industrial computer control operation

. High efficient, easy to operate CNC cutting system

. Z axis automatic tracking function

Applications display

Applied to various metal sheet cutting and punching and other kinds of laser processing, such as hardware, consumer electronics components, various instruments, sheet metal processing industrial cutting; precision cutting and drilling for various metal materials.